Description

Mechanical Properties of T300 3K

| Value | |

| Tensile Strenght [MPa] | 360 |

| Tensile Modulus [MPa] | 23.5 |

| Elongation at break [%] | 1.50 |

| Density [g/cm3] | 1.76 |

| Yeld [tex] | 198 |

| Specific Heat [cal/g °C] | 0,19 |

| Volume Resistivity [ohm cm] | 1.7×10-3 |

Carbon fiber braided sleeves

| Code |

Diameter |

| 8.001.01.D25 | 25 mm |

| 8.001.01.D60 | 60 mm – 35 g/mq |

| 8.001.01.D80 | 80mm – 45 g/mq |

| 8.001.01.D95 | 95 mm – 49 g/mq |

| 8.001.01.D100 | 100 mm – 122 g/mq |

| 8.001.01.D130 | 130 mm – 160 g/mq |

| 8.001.01.D180 | 180 mm – 205 g/mq |

| 8.001.01.D200 | 200 mm – 205 g/mq |

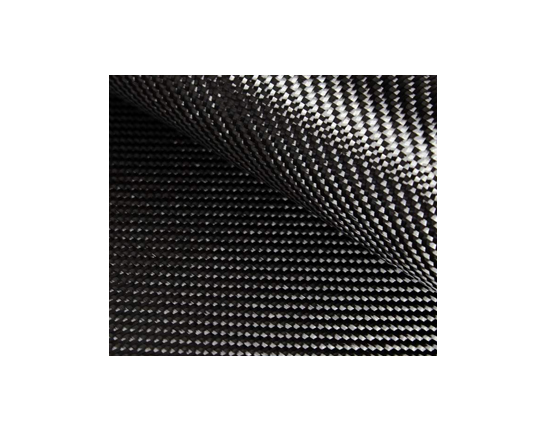

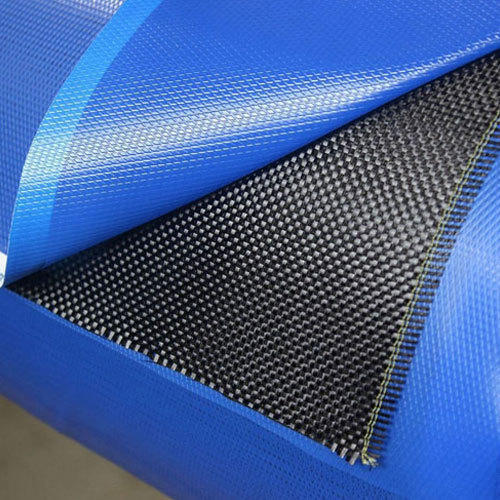

Description

Carbon Fiber Textile

| Code |

Diameter |

| 8.001.02.C201 | Textile C201 |

| 8.001.02.C206 | Textile C206 |

Carbon Fiber Textile C206 Properties

| Typical Value | Standard | |

| Weight | 200±4% | UNI EN 12127 |

| Thickness [μm] | 450±15% | UNI EN ISO 5084 |

Counts [threads/cm]

| Typical Value | Standard | |

| Warp | 1.25±0.3 | UNI EN 1049-2 |

| Weft | 1.25±0.3 | UNI EN 1049-2 |

Carbon Fiber Textile C201 Properties

| Typical Value | Standard | |

| Weight | 194±4% | UNI EN 12127 |

| Thickness [μm] | 250±15% | UNI EN ISO 5084 |

Counts [threads/cm]

| Typical Value | Standard | |

| Warp | 4.90±0.3 | UNI EN 1049-2 |

| Weft | 4.90±0.3 | UNI EN 1049-2 |

Description

Carbon Fiber BAND

| Code | 8.001.03.BCF50 |

8.001.03.BCF100 |

| Description | TCU 420 H50 | TCU 420 H 100 |

Description

PREPREG is a big advantage for the production because is possible to have the same ratio/percentage between resin and fibers in the prepreg, easy to laminate, and more efficient control of the properties of the composite reliability and homogeneity of the laminate and process repeatability.

| Code |

Description |

| 8.001.02.M30SC | Texipreg unidir M30SC-200-DT120-36EF H 600 mm |

| 8.001.02.PC202 | Prepreg CC202 ET223 |

| 8.001.02.PC206 | Prepreg CC206 ER440 |

| 8.001.02.PCBX400 | Prepreg CBX400 |

| 8.001.02.PCBX600 | Prepreg CBX600 |

| 8.001.02.PCHS180 | Texipreg unidir. HS 180 prepreg H 600 mm |

| 8.001.02.S2540 | Texipreg unidir S2 540 g/m |

| Code: 8.001.02.PC206 |

Description |

| Weave Style | Twill 2×2 |

| Fiber Orientation | 0° / 90° |

| Width | 1 m |

| Warp Fiber | High strength carbon T700 12K – 8000 dtex (or equivalent) |

| Weft Fibe | High strength carbon T700 12K – 8000 dtex (or equivalent) |

Description

PREPREG CBX Textile (± 45°) Properties

| Code | 8.001.02. PCBX400 |

8.001.02. PCBX600 |

| Material | 100% carbon | 100% carbon |

| Total weight [g/m2] | 400 | 600 |

| Material | 1270 | 1270 |

| Dry thickness [mm] | 0,45±15% | 0,6±15% |

| Weight [g/m2] | 200 | 300 |

| Fiber type | Carbon 12K T700 FC50C |

Compatible with epoxy and polyester resin |