AGGREGAZIONI REGIONE LOMBARDIA POR FESR 2014-2020

The project introduced advanced technologies, commonly used, in the orthopedic sector which is mainly handmade and inefficient:

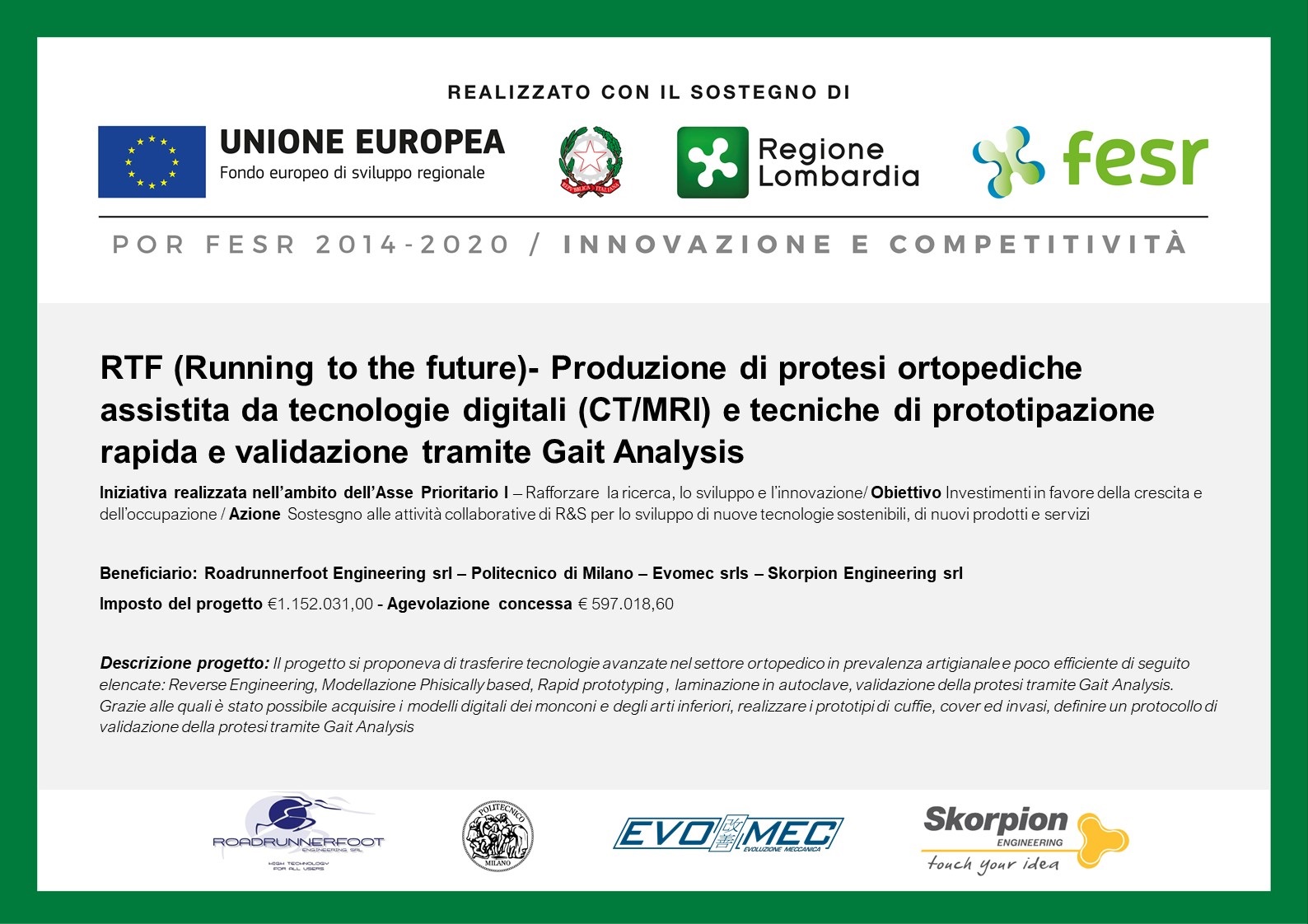

– Reverse Engineering for the acquisition of the 3D model of the stump (residual part of the limb amputee) through CT and MRI, in order to digitally reconstruct the complete 3D model of the stump (skin, muscle parts, soft parts and bones), of foot and leg for making cosmetics customized;

– Physically-based modeling and Fem simulation to generate the “compressed and stylized” model through appropriate compressions, according to the data of the cadavers, to be applied according to the pixels of gray MRI, different in soft parts, muscle parts or bones;

– Rapid prototyping through FDM (Fused Deposition Modeling) creates prototypes through a process of extrusion of a polymeric material filament in the molten state and its deposition layer by layer, up to the definition of the final object. thanks to it the physical model will be realized stylized on which to laminate the socket;

– Autoclave lamination of prepreg fabrics which will allow for the creation of lighter and, at the the same time, more resistant;

– Customization of foot and leg coverings thanks to reverse engineering;

– Validation of the prosthesis through Gait Analysis.

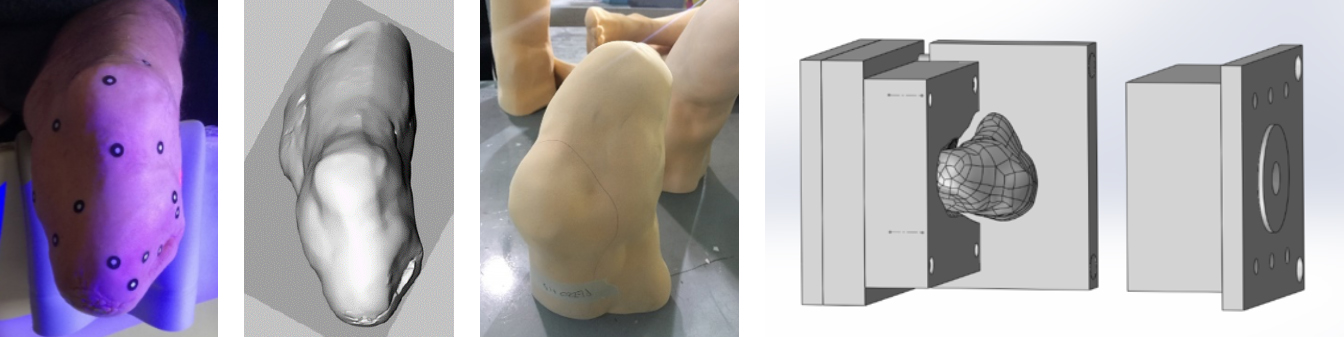

EVA cover foot

Polyurethane cover foot