Integration of innovative methodologies to design and develop “custom-fit” product: application and validation for the socket of the lower-limb prosthesis.

POLITECNICO of MILAN (during philosophy Doctor of Bonacini 2005-2008)

Nowadays several industries are moving towards configurable or custom-fit products. In the former case, a general common architecture is defined and the choice of specific options (depending on the industrial sector) permits to generate of a new product variant; in the latter case, most of the goods consists of products or devices that have to interface with the human body. They have to be designed and customised according to the human shape. Hence, custom-fit products, especially those with a tight interface with the human body, can’t be completely designed using methods and tools developed for other industrial fields (e.g. mechanical field), for mass production or for modular products, but it is necessary to realize “ad hoc” methodologies.

This proposal refers to this context with the aim of realising a) a new design paradigm for “custom-fit” products, b) integrating innovative methodologies and tools to allow companies to evolve from mass production to the realisation of highly customised (custom-fit) products (see Gothenburg objectives). The study case we shall refer to is a component of a lower-limb prosthesis for trans-femoral amputation, precisely the socket (interface between the residual limb and the mechanical part of the prosthesis) that requires a high level of personalisation.

Physics-based modelling, reverse engineering, rapid prototyping, kinematic analysis and simulation with virtual prototypes are methodologies that can improve and innovate the design process ensuring products customisation.

Four Research Units, University of Bergamo, Firenze, Udine and Politecnico di Milano, with complementary competencies in the mentioned scientific areas, propose a research project whose main scientific objectives are:

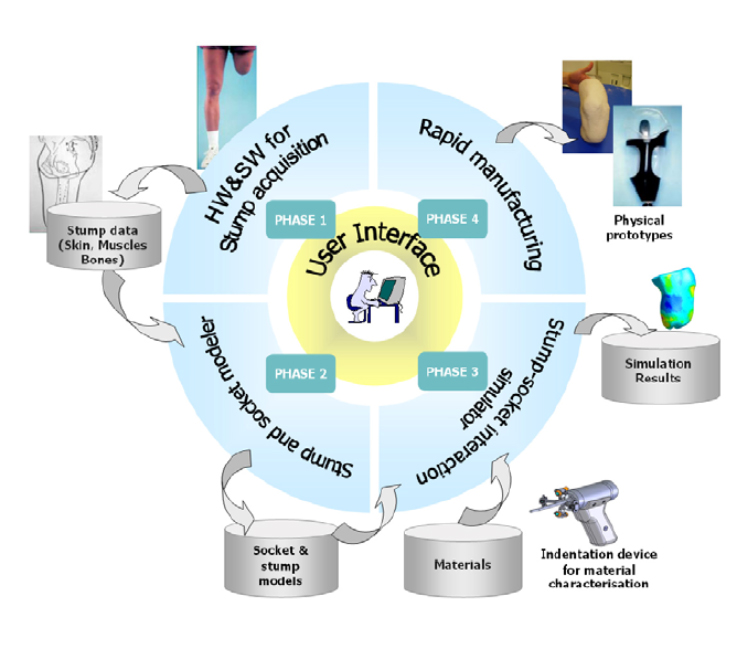

– Definition of a new process development paradigm for “custom-fit” products based on the integrated use of innovative methodologies and technologies;

– Development of an environment to design “custom-fit” products (not yet available on the market) tested with a socket for lower-limb prosthesis and including:

* reverse engineering tools for the automatic (or semi-automatic) acquisition of patient’s morphology and bony-muscular structure (in our case the residual limb) both under static and dynamic conditions;

* a physics-based modeller for “custom-fit” products allowing the designer to represent a product as composed by different materials (inner parts modelling) and overcoming the limits of current CAD systems able to model only rigid and homogenous objects;

* an environment for physics-based simulation to reproduce the real behaviour of the socket-stump system and to verify the product functionalities;

– Rapid prototyping tools for the realization of physical prototypes to test and validate the virtual product and to identify necessary adjustments.

The whole system will be validated through experimental tests in collaboration with the domain experts (e.g., the technicians and the medical staff) and patients with transfemoral amputation.

The proposed environment should allow designers to validate their design choices through the analysis of the virtual prototype and simulation results. It would permit, furthermore, to reduce product development time (2-5 days average), to reduce costs (in Italy charged to the National Healthcare System), to reduce psychological and social impact.

The research goal has a relevant and innovative scientific relevance and represents a significant advance in respect to the traditional systems supporting the development process of custom products.

None of the Research Units has the know-how required to meet the project objectives on its own. The complementarity of competences and the groups’ synergy planned in the research activities guarantee the presence of the entire knowledge required to meet the expected results.

Fig. 1

Example of tight bone amputation

Figure 2

Example of the socket for a trans-femoral prosthesis

Fig. 3.

The design process and related tools for the considered custom-fit product are shown in

Design process

During the project, companies producing prostheses (e.g., Centro Protesi INAIL, Budrio-BO) and patients with transfemoral amputation will be involved in order to identify proper technical specifications and to test methodologies that will be developed.